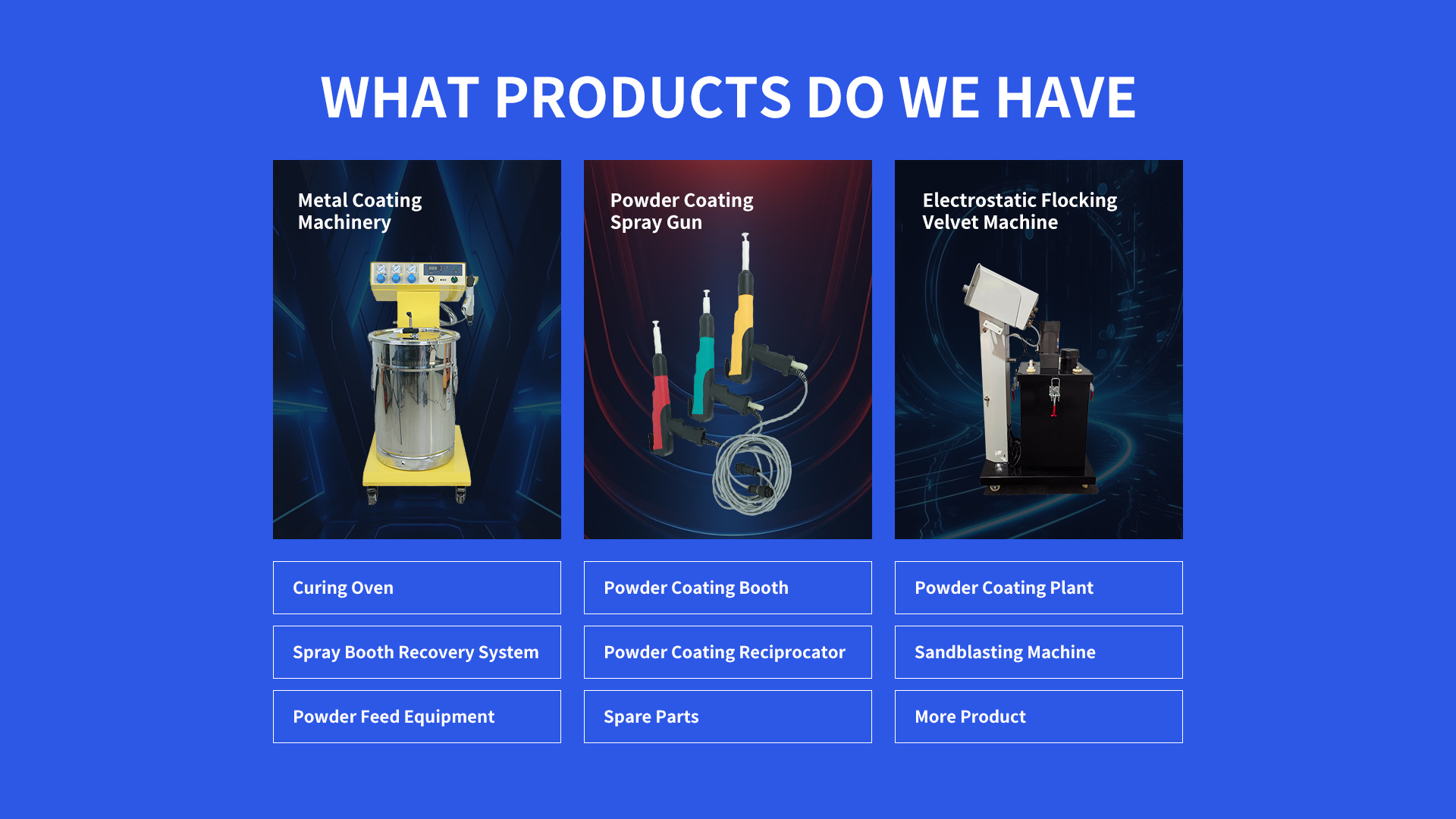

1. Small Powder Coating Machine Overview and Components

Small Powder Coating Machines are compact systems designed for applying dry powder coatings to small or medium-sized parts. Key components include a spray gun, powder hopper, electrostatic generator (in advanced models), power supply, and grounding cable. Built from lightweight aluminum or durable plastics, these machines are ideal for workshops, repair shops, and DIY enthusiasts.

2. Applications of Small Powder Coating Machines

These machines are perfect for automotive part restoration, furniture refinishing, bicycle frames, metal crafts, and small machinery components. They provide a cost-effective solution for hobbyists and small businesses needing professional-quality finishes without industrial-scale equipment.

3. Small Powder Coating Machine Pricing

Prices range from 200forbasicmanualmachines∗∗to∗∗5,000+ for advanced electrostatic models. Mid-range options (500–2,000) typically include adjustable voltage controls, ergonomic designs, and powder recovery systems. Custom features like extended warranties or specialized nozzles increase costs.

4. How to Use a Small Powder Coating Machine Correctly

Ground the workpiece and machine to prevent static buildup.

Adjust the powder flow rate and voltage (30–70 kV for electrostatic models).

Maintain a 6–12 inch spray distance for even coverage.

Cure coated parts in an oven (300°F–400°F) for 10–20 minutes.

Clean the nozzle and hopper after each use to avoid clogs.

5. How to Choose a Small Powder Coating Machine

Project Type: Opt for manual machines for simple tasks or electrostatic models for complex shapes.

Powder Compatibility: Ensure the machine works with epoxy, polyester, or hybrid powders.

Safety Features: Look for grounded cables, overload protection, and ergonomic grips.

Brand Reputation: Select suppliers offering warranties and customer support.

6. Safety Tips for Small Powder Coating Machines

Wear NIOSH-approved respirators, gloves, and goggles.

Work in well-ventilated areas to avoid inhaling fine particles.

Ensure proper grounding to eliminate fire risks from static sparks.

Keep flammable materials away from the workspace.

7. Design Advantages of Small Powder Coating Machines

Modern designs focus on efficiency and user comfort. Features like quick-change nozzles, adjustable spray patterns, and powder recovery systems minimize waste. Lightweight builds reduce operator fatigue, while electrostatic models improve adhesion by up to 50% compared to manual spraying.

8. Small Powder Coating Machine Q&A

Q1: Can small powder coating machines handle automotive parts?

A: Yes, electrostatic models provide durable finishes for wheels, engine parts, and brackets.

Q2: Do I need an oven for powder coating?

A: Yes, curing is essential. Some machines include compact ovens, or use a standard kitchen oven (dedicated to coating).

Q3: How often should I clean my powder coating machine?

A: Clean the machine after each use to prevent clogs and ensure consistent performance.

Q4: Are small powder coating machines eco-friendly?

A: Yes, they produce zero VOCs, and excess powder can be reused.

Q5: What’s the key to avoiding uneven coatings?

A: Maintain consistent spray distance, ground the workpiece, and pre-clean surfaces.

This guide provides essential insights into small powder coating machines, helping buyers achieve professional results while prioritizing safety and efficiency in their projects.

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com